When looking for the best way to measure warpage and flatness, it is important to consider the type of measurement system to use and the installation environment. Selecting equipment that doesn't adequately meet your needs can lead to insufficient precision and increased man-hours during production. This site is designed to help those looking for a warpage and flatness measurement system discover the best way to do so with confidence.

Find the best measurement method and the right equipment to measure "Warpage and Flatness".

Optimal measurement system Laser Displacement Sensor

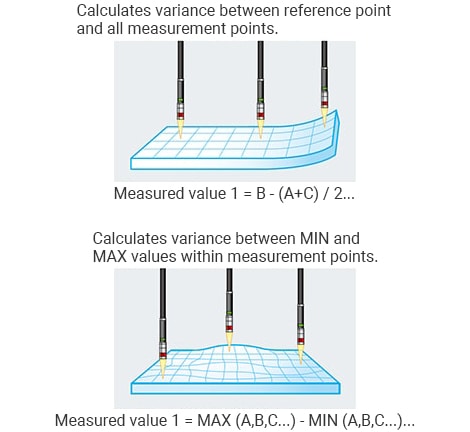

Warpage and Flatness are measured by calculating the height difference obtained by multiple sensor heads at different locations on the part.

KEY POINTS

Measurement errors caused by vibrations from when an individual sensor head is moved to the different measurement locations do not occur.

Because the sensor heads are not moved, inspection cycle times are fast.

No mechanism for moving the sensor head is required.

Multi-color confocal method

CL Series

View Catalog

Spectral Interference Method

SI Series

View Catalog

Optimal measurement system Laser Displacement Sensor

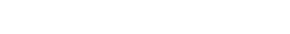

The target or sensor must be moved, warpage and flatness is calculated by the data collected at each measurement location.

KEY POINTS

Only one head is used, so costs can be reduced.

Vibration from when the sensor heads are moved causes measurement errors.

A mechanism for moving the sensor head is required.

Multi-color confocal method

CL Series

View Catalog

Spectral Interference Method

SI Series

View Catalog

Optimal measurement system 2D Laser Displacement Sensor

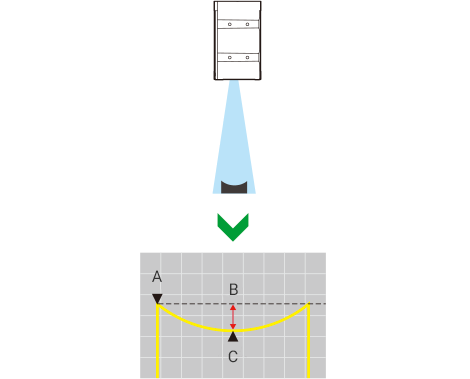

A laser line is reflected from the target surface, warpage is measured by evaluating the height differences on the reflected profile.

A

Peak

B

Warpage amount

C

Bottom

KEY POINTS

Warpage can be measured without moving the sensor head.

2D Triangulation Method.

LJ-X Series

View Catalog

Multi-color confocal method

CL Series

View Catalog

INDEX