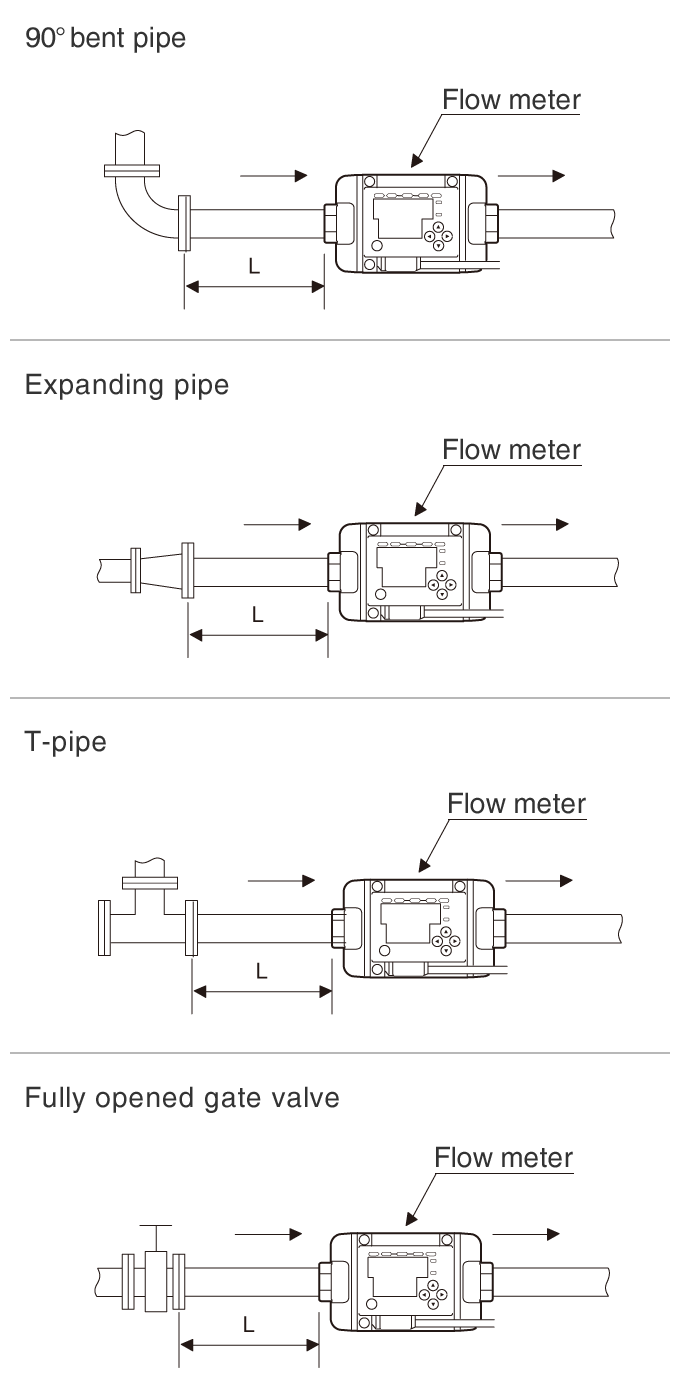

Piping techniques for accurate flow control

In order to use a flow sensor under the most reliable conditions, it is necessary to consider the piping and position of the flow meter installation. Though not absolutely necessary, these suggestions should be followed in order to best stabilize flow measurement.

Creates a laminar flow state

L = 5D or more

L represents the length of a straight pipe section and D represents the nominal bore diameter of the flow meter unit.

You should always attempt to install a section of straight pipe equivalent to 5 times the bore diameter to the upstream side of the flow meter. This limits turbulent flow and creates a laminar flow state.

*For information on "laminar flow" and "turbulent flow" please refer to part 7 of chapter 3.Creates a full volume state

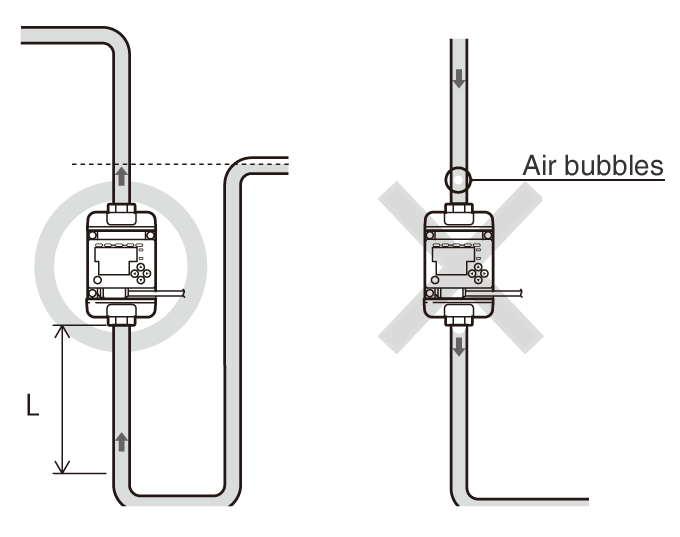

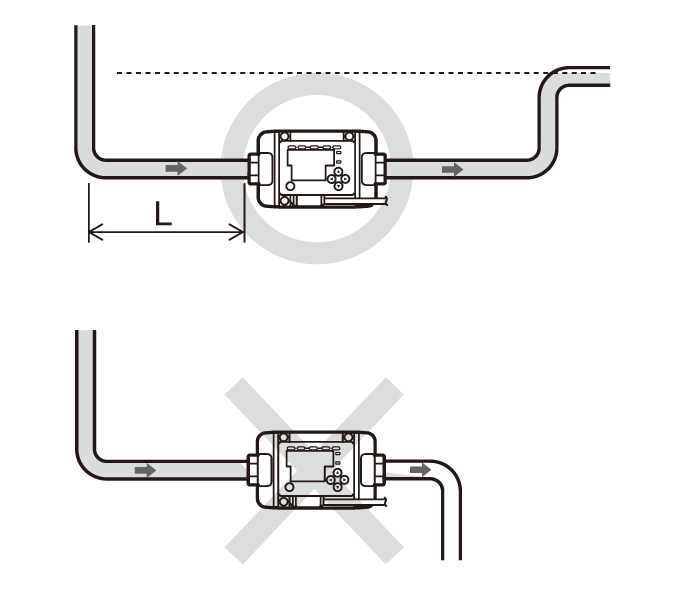

Flow sensors best measure flow when the flow path is in a full volume state. Water accumulates in lower sections due to gravity. When water flows in piping like the illustrations above and below, a full volume state is maintained.

Creates a full volume state

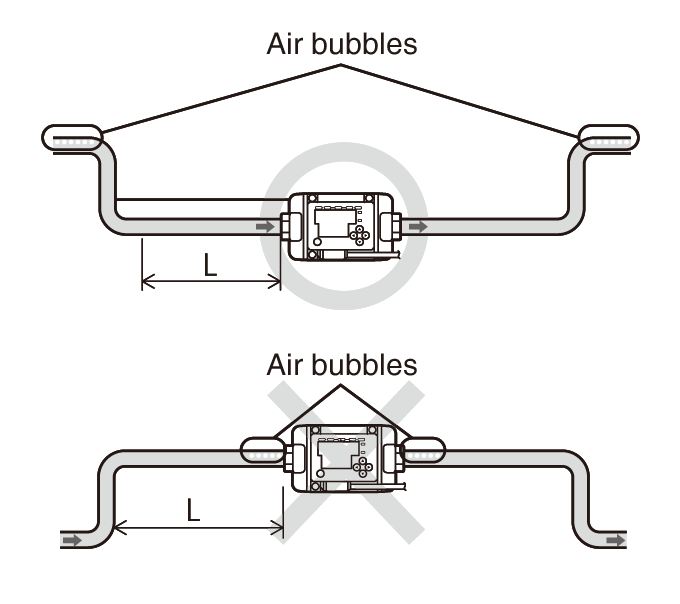

Prevents air bubbles from mixing into the fluid

Air bubbles collect in the upper sections of water. When the piping is bent as in the top illustration, it is possible to prevent bubbles from mixing into the fluid.

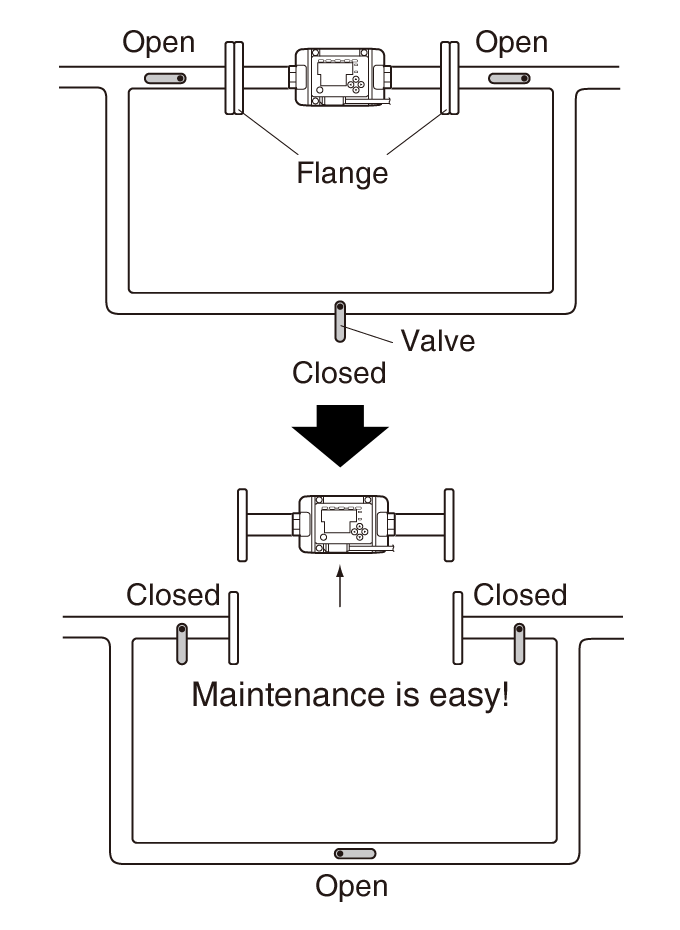

Improves maintenance ability

CHAPTER 4

PRESSURE LOSS