Plastic/Resin

- Major types of marking/processing

- Mechanism of plastic color development

- Ratio of absorption into plastic

- ABS Plastic

- Epoxy Plastic

- PET Plastic

This section introduces the basics of plastic laser marking and processing. Learn how laser markers are used on plastic parts (such as ABS, epoxy and PET) and see some marking examples.

Major types of marking/processing

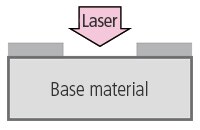

1: Paint peeling

Peel the paint or printing on the target surface to bring out the contrast with the color of the base material.

(Example) Automobile instrument panel switch

Conventional methods (like printing and stamping) require full plate changeovers when a design change occurs. With a laser marker, you can adjust layouts by simply changing the program.

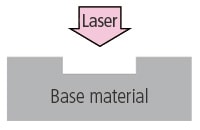

2: Surface layer peeling

Remove/engrave the surface layer with a laser.

(Example) Half cut

A laser marker can be used to easily process a cutting section. Physical cutters are conventionally used in these scenarios, but they're difficult to adjust and time-consuming to change. Moreover, physical blades must be replaced often (incurring hard costs) and there's a risk that the blade will come loose and get left in the product.

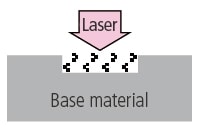

3: Color development

Irradiate a plastic target with a laser to develop a color in the target itself.

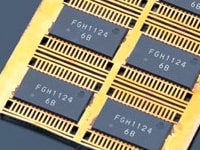

(Example) Wide-area marking on LSI

By using laser radiation to develop a color instead of engraving the plastic, damage from marking the target is minimized.

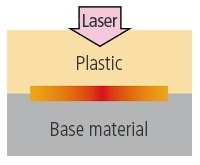

4: Welding

Use the heat of laser radiation to weld and join plastic parts.

(Example) Welding of transparent plastic and colored plastic

Traditional welding can cause vibration which may affect the product or produce burrs. Since laser welding does not make contact with products, it won't damage them or produce burrs.

Mechanism of plastic color development

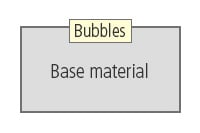

1: Foaming

When a base material is irradiated with a laser, gas bubbles are generated inside the material due to the thermal effect of the radiation. Gasified, evaporated bubbles are contained in the surface layer of the base material and create a whitish swelling. When the base material has a dark color, the swelling is highly visible and typically lighter than it was before marking.

- (Example) Base material color:

-

- Black→

- Changes to Gray

- Red→

- Changes to Pink

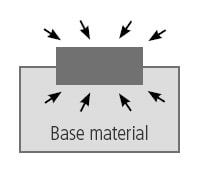

2: Condensing

When a base material absorbs the laser energy, the thermal effect increases the molecular density.

The molecules are condensed and the color becomes darker.

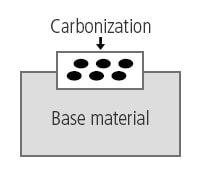

3: Carbonization

When an area is continuously irradiated by laser light, macromolecules of the element around the base material are carbonized and turn black.

4: Chemical change

The “pigment” elements in a base material typically contain metallic ions. Laser radiation changes the crystal structure of the ions and the hydration level in the crystal. Consequently, the composition of the element itself changes chemically, resulting in color development due to the increased intensity of the pigment.

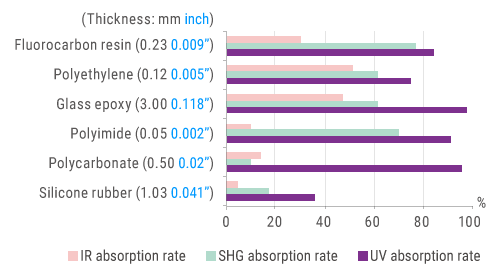

Ratio of absorption into plastic

Ratio of absorption into materials depending on wavelengths

The graph below shows the absorption rates of various laser wavelengths on common resins The graph includes data on fundamental lasers (1064 nm), green lasers (532 nm) and UV lasers (355 nm). As a laser's wavelength becomes shorter, it's absorption rate on most plastic increases. Therefore, UV lasers are typically the best systems to choose for resin marking applications.

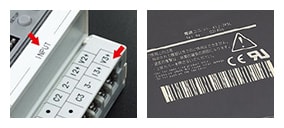

ABS Plastic

Black-Annealed Marking / White Marking

Laser irradiation produces highly visible black / white marks depending on the target plastic's color. As a result, laser marking provides a printing-like finish that cannot be erased.

Selection factors

Mark contrast and density are both important factors to consider when choosing a laser marker for plastics. Laser markers capable of producing a high peak power are optimal (such as a hybrid 1064 nm laser or UV 355nm laser). CO2 laser markers can be used as well, but they do not typically discolor plastic surfaces.

Recommended model

3-Axis UV Laser Marker MD-U Series

Epoxy Plastic

White Marking

Laser markers can easily create clear, white marks on epoxy plastics. They're great replacements for stamps, labels and printers. The highly-visible, print-like markings do not disappear like ink.

Selection factors

Shifting a laser marker's focal point allows for high-grade printing with good visibility, all while keeping the marking depth to a minimum.

Recommended model

3-Axis Hybrid Laser Marker MD-X Series

PET Plastic

White character marking is possible on transparent/translucent PET plastics. Laser markers are able to mark PET bottles, thin films and most products in-between without leaving pin holes.

Selection factors

High-powered laser beams can overheat targets and create pinholes. CO2 lasers with a short wavelength (9.3 μm) enable clear marking with minimal damage.

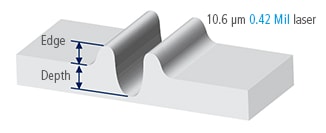

- Standard wavelength

-

Conventional method

Damage is excessive and engravings are deep and rough

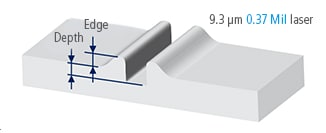

- Short wavelength

-

ML-Z

Damage is minimal and engravings are shallow and sharp

Recommended model

3-Axis CO2 Laser Marker ML-Z Series