Glass, Paper, Ceramics, and Other

Laser markers are able to perform a wide variety of applications thanks to different laser types and wavelengths. Not all laser markers interact with materials the same way, so it's important to choose the optimal laser marker for your application.

This section highlights other commonly marked materials (such as glass, paper and ceramics) and shows some common marking examples and the ideal laser for the job.

Glass

Soda glass

Marking is achieved by generating minute cracks on the glass. Repeated marking at lower power allows for clearer marking.

-

- Single-pass marking at high power

- Several large cracks are generated

-

- Multi-pass marking

- Overall marking quality is uniform

Selection factors

CO2 laser markers that perform marking by applying heat to the target are optimal. Marking at high power can sometimes cause large cracks, so making multiple passes with low-power marking is most effective. Defocusing allows for adjustment of the thickness of lines.

Recommended model

3-Axis CO2 Laser Marker ML-Z Series

Quartz Glass

Thermal marking melts the surface of the glass. Because quartz glass is heat-resistant, laser marking is possible without the generation of cracks.

Selection factors

CO2 laser markers that perform marking by applying heat to the target are optimal. With heat-resistant quartz glass, marking may need to be done slowly at high power to create high visibility.

Recommended model

3-Axis CO2 Laser Marker ML-Z Series

Paper

White Marking by Removing Pre-Printed Surfaces

High-visibility marking is achieved by burning the printed surface (solid coating) using the laser. The high-contrast result allows for highly readable barcodes and other detailed marking.

Selection factors

CO2 laser markers that perform marking by applying heat to the target are optimal. Darker pre-printed surfaces allow for greater visibility. Marking for barcodes or other applications tend to take more time than regular character marking.

Recommended model

3-Axis CO2 Laser Marker ML-Z Series

Marking on Unprinted White Paper

Marking is achieved using a high-power laser to burn the white surface of the target. When upgrading from stamping or other methods, there's no need to change the designs of cartons or other products, ensuring a smooth transition.

Selection factors

CO2 laser markers that perform marking by applying heat to the target are optimal. Residue may also be generated while marking, so a dust collector in addition to the laser marker may be required.

Recommended model

3-Axis CO2 Laser Marker ML-Z Series

Ceramics

With zirconia ceramics, marking appears black as if the surface was burnt. With alumina ceramics, marking appears as if the surface has been melted.

Selection factors

For zirconia ceramics, laser markers with the fundamental wavelength are optimal, and for alumina ceramics, CO2 laser markers are optimal. Take care when selecting the laser marker model, as the best choice will change depending on the ingredients of the target.

Recommended model

3-Axis Hybrid Laser Marker MD-X Series

3-Axis CO2 Laser Marker ML-Z Series

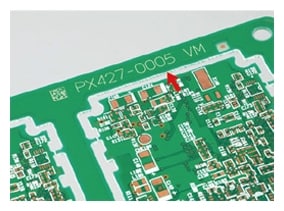

Printed Circuit Boards

White marking is performed by engraving only the surface of the solder mask. The shallow engraving allows for clear marking without exposing the pattern.

Selection factors

Low-powered laser marking should be performed on PCBs, as soot will be generated if the marking power is too high. Additionally, near-IR laser wavelengths pass straight through solder masks and risk damaging the pattern. Therefore, CO2 laser markers are the ideal choice for PCB marking applications.

Recommended model

3-Axis CO2 Laser Marker ML-Z Series