Visualization of Fiber Dispersion in Composites

Real-time overlay function combining brightfield and fluorescence

Composites are materials made from combining organic and inorganic materials for the purpose of increasing their strength or coefficient of friction.

The different materials are mixed in the manufacturing process, but they can’t just be combined—they must be evenly blended to produce the intended characteristics.

In performance tests and similar tests, how well the base materials are mixed may need to be examined if the target characteristics are not obtained.

-

Brightfield image

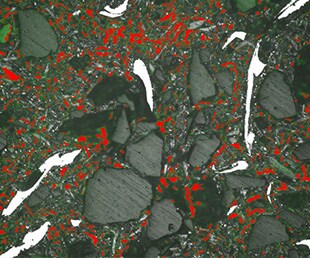

Fluorescence image

-

Overlay image

-

Measurement result image

Area Count Total 9,846,995 µm2 — Fiber section 624,498 µm2 1600 Percentage 6.34% —

Conventional problems

Microscopic observation generally means using an optical microscope or an electron microscope.

However, organic and inorganic materials may often appear to be the same color, making it difficult to visualize the dispersion of only the organic material.

Using the All-in-One Fluorescence Microscope BZ-X800

- In general, with fluorescence microscopes, organic materials shine but inorganic materials do not. Using that characteristic, you can visualize only the organic materials.

- The BZ Series captures continuous fluorescence and optical (brightfield) images instantaneously and easily produces overlay images.By overlaying the brightfield image and fluorescence image, you can clearly observe the dispersion of the organic material while looking at the entire shape.

- The shining parts can very easily be converted to a binary image using quantitative analysis software. This conversion further allows for quantitative evaluation based on substance count, area, and other numeric parameters.

- The large motorized stage also plays a part in the automatic acquisition of multiple images. In cases of large samples where high resolution is preferred but local observation is not sufficient to understand what is happening as a whole, the BZ Series can provide wide field of view images regardless of magnification, thereby enabling accurate evaluation and judgment.

- Here are some examples of using the All-in-One Fluorescence Microscope BZ-X800 in front-line research.

- [Myelodysplastic Syndromes (MDS)] Stitching, Sectioning and the Z-Stack Function as Decisive Arguments for the Acquisition of the BZ Fluorescence Microscope at the University Hospital of Düsseldorf

- [Neuropathology] The perfect solution for everyday patient diagnostics and clinical research at the Institute of Neuropathology in the Charité hospital in Berlin

- [Regenerative Medicine] BZ Series Provides Essential Imaging for Neural Stem Cell and Spinal Observation

- [Gene Therapy] Improving Research for the Development of Gene Therapy Drugs

- [Heart Disease Treatment] Developing Cell Sheets for Myocardial Regenerative Treatments

- [Cancer Treatment] Automated Fluorescence Microscope Transforms Process for Induced Cancer Stem Cell Research

- [Immune System] BZ Series Contributes to Understanding the Pathological Model of Asthma

- [Biomaterials] Promoting Efficiency in Research With Compact, User-friendly Microscopes