- Home

- Solutions

- Case Studies

- KEYENCE Systems Bring Automated Inspection to Motion Dynamics

KEYENCE Systems Bring Automated Inspection to Motion Dynamics

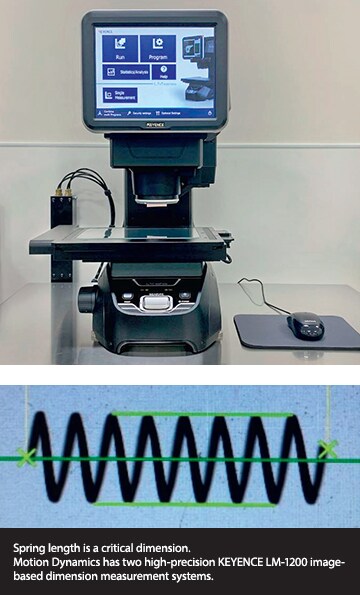

Over the past five years, a US-based manufacturer of precision springs, coils, and wire forms has advanced its in-house inspection capabilities with the implementation of five KEYENCE image-based dimension measurement systems and two KEYENCE digital microscopes.

Motion Dynamics Corporation, headquartered in Fruitport, Michigan, supplies markets such as medical, aerospace, electronics and automotive with a range of springs, coils, and wire forms. Founded in 1992, the company has grown quickly, and today it employs 175 people at its 73,000 ft2 (6782 m2) custom-built facility.

“We are focused on solving customer problems in the shortest possible time – no matter how complex or seemingly impossible – which is what leads to our growth,” explains John McManus, Vice President of Engineering. “We like to be innovative and take on projects that others avoid. No one here believes in saying no. We’re not afraid to invest in new technology if that’s what it takes to deliver the solution. As a result, we’ve developed some of the industry’s most innovative products; products no one else in the world can make.”

Small parts, big innovation

With the company manipulating wire as small as 0.0005” (0.0127 mm) in diameter, some of the springs and coils that Motion Dynamics produces measure less than a grain of salt. Of course, high levels of quality control are required to ensure such parts meet the demanding specifications of customers. Motion Dynamics’ primary industry, the medical industry, sets out an AQL (acceptable quality level) which specifies how many parts require measurement in relation to the lot size – and for which features. Motion Dynamics holds accreditation to ISO 13485, the international quality management system for medical devices.

“The type of measurement equipment used is determined by the part features, tolerances and lot sizes being inspected,” states McManus.

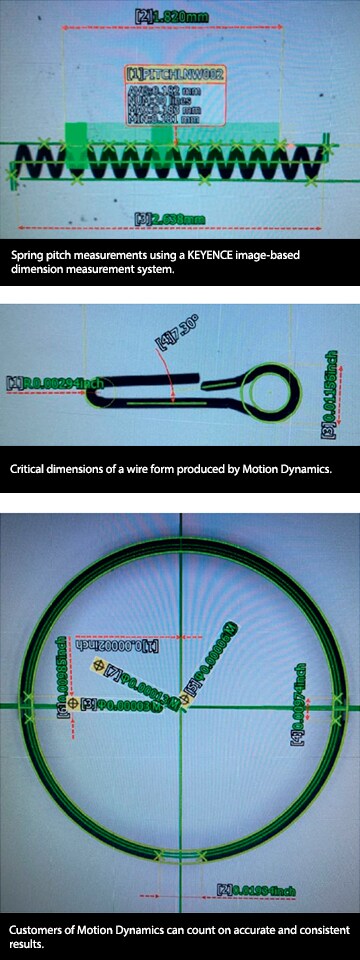

General tolerances for outside diameter (OD) measurements at Motion Dynamics include ±0.0002” (±0.005 mm) for micro springs and ±0.002” (±0.05 mm) for standard-sized springs. Length is also closely controlled, typically to ±0.002” (±0.05 mm) on micro springs.

Image-based dimension measurement

Until recently, Motion Dynamics performed its inspection using manual vision systems, which typically feature XYZ stages with glass scales and high-resolution cameras. While accurate, growing throughput requirements and increased demand for 100% inspection prompted the company to investigate automated, image-based dimension measurement systems, and they acquired a KEYENCE Instant Measurement System in December 2016. Motion Dynamics has since purchased the two additional units to further accelerate quality inspection, along with two KEYENCE LM High-Accuracy Measurement Systems, which deliver ±0.000039” (±0.001 mm) accuracy. Motion Dynamics also owns two KEYENCE VHX Series Digital Microscopes.

“The most recent arrival, in February 2021, was our second LM-1100,” says McManus. “Every time we look to invest in a new KEYENCE system, there are new advancements, which is great, as we’re always looking to improve our capabilities for the benefit of our customers.”

Motion Dynamics parts are difficult to measure. Using round wire most of the time means the springs and coils have 3D depth, which present a challenge in the 2D plane because of the silhouette around the component. KEYENCE’s metrology equipment has helped Motion Dynamics overcome this challenge.

“Our focus has always been to invest in the best equipment, as it ensures we can measure very challenging part geometry,” says McManus. “The KEYENCE LM-1100 models are the most powerful systems on site for accuracy! We can inspect multiple components simultaneously without having to define how many parts are on the stage, making it a very flexible resource. In addition, we can collect and export data automatically for part validations and analyses, helping us to improve Gage R&R (Gage Repeatability and Reproducibility) results on difficult-to-measure components.”

Safety-critical applications

Quality is critical because of the demanding markets served by Motion Dynamics and because lives depend on it, quite literally. Whether it be parts for medical devices, aerospace assemblies, or springs for high-precision defense applications, customers expect very high quality, often a level they are unable to find anywhere else.

“The KEYENCE systems have brought automation to our mainstream inspection activities,” states McManus. “Additionally, customers can count on accurate and consistent results as the KEYENCE solutions remove the potential for differences between operators when using manual inspection systems.”

Motion Dynamics continually looks to improve its levels of innovation and capability. The company’s business model is based on solving challenging problems in short lead times, which is where the KEYENCE systems prove invaluable.

“We have a large mix of high-precision and wide-field part applications, which is why we have a variety of KEYENCE Instant Measurement Systems in use,” says McManus. “However, the high-precision travel of the LM units cover more of our precision part measurement needs. In the future, we could very well look at the latest version of the IM or LM Series at the time as yet another advance.”

APPLICABLE PRODUCT CATALOG

Related Products

-

- Image Dimension Measurement System

IM-8000 series

- Image Dimension Measurement System

- PLEASE

CONTACT US