Metal

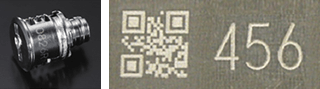

Learn how laser markers affect different metals and which lasers are best suited for metal marking applications.

Keep reading to see examples of aluminum, stainless steel, iron, copper, cemented carbide, and gold plating.

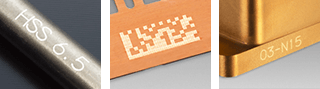

Main Marking Types

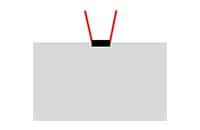

Black Annealed Marking

Defocused laser light creates a smooth, black mark on the surface of a part.

The following materials anneal well

Recommended Laser Marker model

3-Axis Hybrid Laser Marker MD-X Series

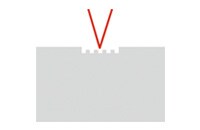

White Etch Marking

Laser light irradiates the target, melting the surface and creating many small and highly reflective pools. These bright pools will appear white.

The following materials etch well

Recommended Laser Marker model

3-Axis Hybrid Laser Marker MD-X Series

Engraving

Laser light irradiates the surface, etching away layers of the material. Repeated etches on the material will result in a deep engraving. This method allows users to engrave and mark with no coloration (similar to stamping). Laser engraving provides various benefits, such as allowing visibility even after the mark gets painted over.

The following materials engrave well

Recommended Laser Marker model

3-Axis Fiber Laser Marker MD-F series

Surface Peeling

Laser light irradiation peels off the surface layer leaving the base material visible.

The following materials peeling well

Surface peeling will work well on any painted or coated metal.

Recommended Laser Marker model

3-Axis Hybrid Laser Marker MD-X Series

Main Processing Types

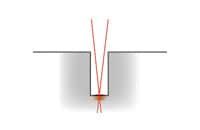

Cutting

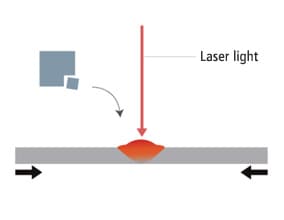

Laser light irradiates a fixed point, usually with repetition to melt the material. The laser can easily melt through thin metals, fabrics, and leather. Because there is no contact, it does not cause a reaction with the item processed. Deformation and cracking is kept to a minimum. In addition, because it is possible to specify processing areas in extreme detail, it is possible to create localized holes or cuts in places where traditional cutting tools cannot fit.

Soldering

Laser irradiation is used to heat solder paste that then joins metals. This irradiation is highly localized allowing for extremely precise soldering compared to traditional methods. This precision also reduces the head effected zone on the parts.

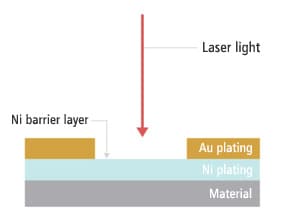

Solder Barrier

Electronics continue to get smaller and thinner. As a result, connector terminals need solder barriers (nickel barriers) to stop the soldering from expanding. Conventionally, masking was used on locations where electroplating was not necessary. However, removing the mask material took time and effort. Surface layer removal using laser light is effective in these cases.

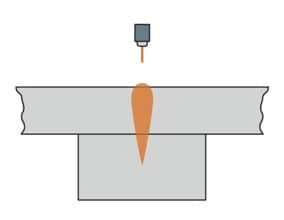

Welding

Laser welding irradiates two targets at the focal point and joins them together by melting and the soldifying the metal. It is possible to irradiate a pinpoint with high density energy and complete the process at high speeds. Material distortion due to heat is kept to a minimum. In the past, deformation occurred easily, but now even thin materials can be welded.

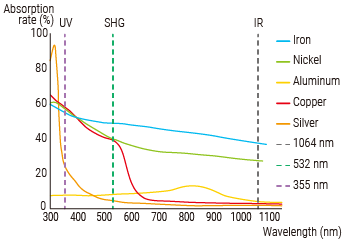

Absorption Rate for Metals

This graph shows the different absorption rates of metal materials with a UV laser (355 nm) and a fundamental laser (1064 nm). There is no significant change to the absorption rate for iron (Fe), nickel (Ni) or aluminum (Al) when the wavelength is changed. However, the absorption rate for gold (Au) and copper (Cu) is affected greatly by changes in wavelength. The absorption rate for gold (Au) with wavelengths of 355 nm is approximately 30%, but with the fundamental wavelength of 1064 nm the absorption rate is less than 10%. Similarly, with a wavelength of 355 nm, copper (Cu) has an absorption rate of 60%, whereas that rate is less than 10% with the fundamental wavelength of 1064 nm.