Handheld Computers

Handheld computers speed up data collection for many business-critical applications in industries such as manufacturing and logistics. Improve work efficiency with a large touch screen and ability to instantly read dirty or distant barcodes. The OCR function can optmize work even if no barcodes are present.

Lineup

The DX Series is a high-speed, rugged, and flexible PDA designed for enterprise purposes. It solves the problems of increasingly complex applications and improves efficiency at various worksites. The DX Series comes with two different screen sizes—six inches and four inches—to match differing application needs. The ergonimic, one-handed grip, makes the DX Series easy to use even with the large six-inch screen and the high capacity 6060 mAh battery allows operators to work uninterupted. Not only does the DX Series provide high-speed reading and excellent durability, but the RFID reader and other expansion units allow it to flexibly respond to on-site changes.

Features

Options for Any Operation

Two available screen options—six inches and four inches—are suitable for any user. With lighting fast scanning, the DX Series increases productivity by speeding up data acquisition. The rugged design eliminates downtime caused by repairs in normal or extreme environments.

Two Screen Sizes Available for Different Worksites

- Large six-inch LCD and compact four-inch LCD

High Speed Reading for Increased Productivity

- Equipped with KEYENCE’s proprietary algorithm

- Improved reading performance for increased operation efficiency

- High speed and reliable code reading

Rugged Design for Use in Harsh Environments

- Enterprise means durable

- Drop resistance: 2.7 m 8.9' *

- 3.0 m 9.8' with a rubber bumper *

* This is a test value. The value is not guaranteed.

Multiple Attachment Units for Different Applications

The attachments communicate directly to the device, rather than through Bluetooth®. This allows for faster RFID reading with no programming required. These attachments charge with the same connection as the main unit, requiring fewer cradles and cables.

RFID (High Output) Unit

Quick and easy multi tag scanning

RFID (Medium Output) Unit

Reading and writing of specific RF tags

Ten-Key Pad Unit

Tactile attachment for operator comfort

Gun Grip Unit

Easy targeting at logistics sites

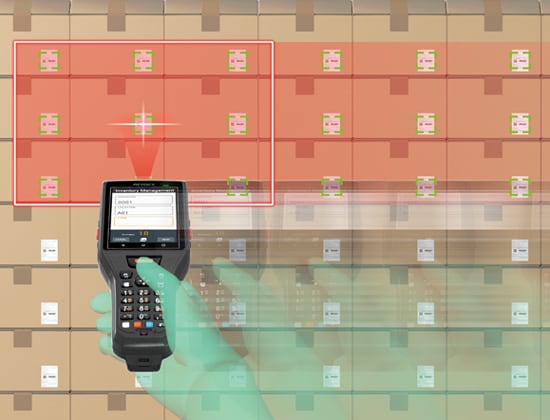

Our new, full-range model of handheld computers, the BT-A700 Series, is capable of reading codes from a minimum distance of 1 in. to a maximum distance of 10m(30 ft). Its impressive reading range and speed enable users to read codes instantaneously in one hand not only while standing but also while seated in a forklift. This leads to impressive productivity improvements. The combination of the first-in-class full-range camera and ultra-high-speed decoding allows instantaneous reading of barcodes even from an angle. The ease of on-site use has also been greatly enhanced. The compact body with a largest-in-class 5-inch screen offers excellent grip to allow stable one-handed operation. Rugged design with a tempered glass screen withstands drops from heights of 2.4 m (8 ft). The device can also be used continuously for up to 32 hours.

Features

The First-in-Class Full-Range Camera

KEYENCE developed a proprietary full-range camera capable of capturing codes at the optimum focal point from near-range to far-range distances. This enables code reading across the entire range.

![[Super-high-brightness lens] [Full-range camera] [Laser sight] [High-speed DSP core] Point and read laser sight function](jpg/series_bt-a700_features_01_1973326.jpg)

Excellent One-Handed Operability

The reader is easy to point at the target and uses a gun-grip shape that fits easily in your hand. We combined the conventional design with intuitive built-in keys enabling single-handed operation.

Before

Input using both hands

After

Input using one hand

The BT-A500 Series Handheld Computer with Android™ OS dramatically improves on-site efficiency by boosting the speed of repeated daily tasks. In addition to the ability to instantly read codes under any conditions, the shape of the device is optimized for Android OS performance, allowing for fast one-handed operation. This model also has excellent durability for tough conditions. The rigid chassis and damper mechanism enables the device to withstand drops from 2 m(6.6 ft) as well as 20000 repeated impacts from 30 cm(0.98 ft). Built-In implementation, maintenance, and support tools are also available. The kitting function allows users to copy settings from a single unit to multiple devices and the remote access function enables support and troubleshooting of a device independent of its location.

Features

Instant Reading of Challenging Codes

Instant Reading Even when Codes are Damaged or Plastic Wrapped

Plastic wrapping

Wrinkled

Damaged

Conventional Models

Unreadable due to plastic wrapping

BT-A500

Readable even with plastic wrapping

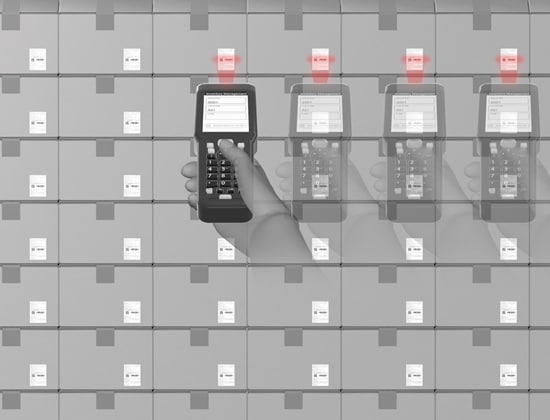

Batch Reading of Multiple Codes

Conventional Models

Reading many codes takes time

BT-A500

Batch reading for faster data collection

Scan Any Printed Text in Addition to Codes

Conventional Models

Time-consuming inspection, recording, and manual logging

BT-A500

Instant reading of any text

Examples of Readable Text

Product label

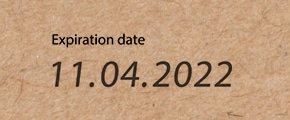

Food expiration date (cardboard)

Pharmaceutical expiration date/lot number

PCB

Fast One-Handed Operation with Hard-Keys and Touch Panel

The device includes a finger rest hook on the back for improved handling and stability. In addition, the LCD panel is raised slightly from the grip to allow for stable one-handed operation of both hard keys and the touch screen.

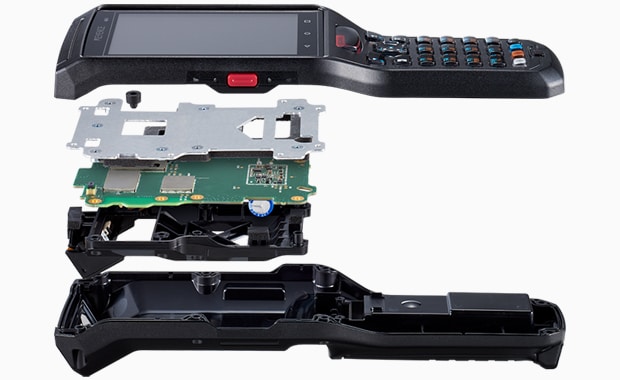

Highly Durable Structure for Tough Conditions

The rigid chassis significantly prevents device deformation and a damping mechanism helps absorb repeated impacts to the main PCB.

The BT-W100 Series Handheld Computer is an information terminal type model offering both one-handed operation and high visibility with a large screen. Its 3.5-inch large VGA LCD can display more information at a time. A viewing angle of 260, twice that of conventional models, enables user's to recognize images and data clearly even when viewing the screen from an angle. Despite the large screen, the lightweight 257g body has been designed to have an easy-to-grasp round shape and center-of-gravity that directs the weight of the device naturally into the users hand. This makes it natural and stable to hold and allows smooth operation, even for one-handed operation. The device also has a battery with high energy density and proprietary power-saving control enables continuous use for 22 hours.

The BT-W80 Series Handheld Computer offers long-term durability. The battery can be used for 23 hours and its body withstands drops from heights of 3 m (10.0') *. It can endure the harshest environments among the lineup to allow reliable use even in severe worksites. The decoding engine has been redesigned to provide greatly improved reading capabilities for difficult-to-read codes and resistance to hand movement. KEYENCE’s proprietary power-saving control and a battery offering high energy density ensure long-duration use. This model also offers high operability based on the easy-to-hold shape, balanced center of gravity, and key layout. This is a handheld computer that resulted from a thorough pursuit of ease of use and reliability on worksites. * 2.5 m (8.5') for the BT-W85.

The BT-W70 Series Handheld Computer is an ultra-lightweight model with a slim design. It is best suited for long-term continuous use. It weighs only 130g, achieving a weight reduction of 30% when compared with conventional products. The compact body with an overall length of just 156 mm (6.14") can be handled easily. This compactness and lightweight allow a significant reduction of loads over long periods of work. Of course, it has all the functionality required by professionals. The proprietary power-saving system has achieved continuous use for 26 hours with stable CPU operation. This allows even worksites to use a two-shift system to save time and labor for charging or replacing battery packs. The robust design even withstands drops from heights of 1.5 m (5.0') as well as continuous impacts.

Handheld computers are highly portable terminal devices used for reading and collecting data concerning items. In recent years, not only can they read barcodes and 2D codes but they are capable of optical character recognition (OCR) to read characters directly marked on products and parts, such as lot numbers and serial numbers, as well as expiration dates. Unlike handheld code readers used for reading codes only, handheld computers have a CPU and LCD screen built into the body. They can be used for various applications through the use of business programs, as well as for information browsing and alert display. Typical applications are inventory, work-in-progress, and process management of parts, products, and raw materials. Handheld computers must provide excellent operability, durability, waterproofing, and dust proofing to enable their use in various worksites in the manufacturing, logistics, retail, and wholesale fields.

Benefits of Handheld Computers

Barcodes, 2D codes, and characters on product slips, instruction sheets, products, and parts can be instantaneously read, converted into data, and recorded.

It is also possible to record additional information such as the time of reading, which greatly improves the efficiency of warehousing and process management.

Some types of handheld computers can use optical character recognition (OCR) to acquire characters, such as serial numbers and lot numbers directly marked on products and parts, as well as expiration dates. This is effective for both reducing man-hours and preventing careless mistakes during the management of products and parts with no barcodes / 2D codes, which were impossible through visual check and manual entry.

After reading one code, handheld computers can read the information linked with the code automatically or can export information automatically to a specified row/column in Excel or other software.

The data read with handheld computers are saved automatically. To make it easier to collect data from each transaction, the saving format can be determined in advance, which reduces the number of work-hours spent on data management.

Some operation-specific applications may require labor and cost for programming. Since handheld computers allow the setting of business applications without programming, they can save development costs and the time and labor required before the start of the operation.

Handheld computers capable of wireless connection allow readout data to be applied to the system in real-time.

With paper-based aggregation, the overall results can be checked only after operations such as inventory and warehousing are complete and the data is entered into a PC. On the other hand, with wireless type handheld computers, the results can be transmitted as the work is being performed, so the status can be checked in real-time. This enables management with no time lag, which was impossible through paper-based aggregation. This prevents careless mistakes when data is created from paper or inventory is made by several workers. It also prevents mixed-up information in workplaces where the inventory changes frequently.

Handheld Computer Case Studies

Logistics

Handheld computers enhance the efficiency of matching delivery statements and cargo during receiving inspection and recording the inspection results at warehouses and distribution centers. They can greatly improve various works for items with no barcodes, such as label issuance, accurate location management when packages are shelved, picking, and shipping. For package transportation, linking the information read with handheld computers to a cargo tracking database enables flexible and real-time management of the location and status of cargos.

For handheld computer application examples of each process, from receiving to shipping, in the logistics industry (warehouses, distribution centers, and cargo transportation), click the button below.

Automotive/Transport Equipment

A car consists of enormous numbers and types of parts. On automotive manufacturing sites, traceability takes on great importance, so handheld computers can significantly improve operating efficiency.

They enable receiving inspection of parts, raw materials, and outsourced parts, allow picking during warehousing, improve the efficiency of inventory management and matching work, and implement error-proofing. In machining and assembly processes, various operations can be done by just holding handheld computers over the target, including real-time progress management, management of fed parts and works in progress, prevention of different parts from being mixed, and recording of manufacturing processes and inspection results.

For handheld computer application examples in the automotive/transport equipment, such as error-proofing and inventory management, click the button below.

Electrical/Electronic Devices and Semiconductors

Installing handheld computers on manufacturing sites of electrical/electronic devices and semiconductors improves the accuracy of receiving inspection, acceptance checking, and expiration date management and picking in raw material warehouses.

In preprocessing, operation management, chemical check, insertion check, and recipe check can be performed in real-time. In postprocessing, such as mounting and assembly, work procedures can be displayed on the screen of handheld computers and careless mistakes can be prevented during parts matching. Management accuracy and work efficiency can also be improved during shipping inspection and in finished product warehouses.

For handheld computer application examples in the electrical/electronic device and semiconductor industry, such as improvement of work accuracy and efficiency and traceability assurance, click the button below.

Food, Pharmaceutical, and Cosmetics

There are strict safety standards in the food, pharmaceutical, and cosmetics industries. In the food industry, in particular, the introduction of HACCP has been made mandatory, resulting in a sharp increase in control items. Installing handheld computers is effective for error-proofing order reception/placement and material insertion and for improving process management efficiency. Just scanning the target item completes operations such as warehousing management linked to the expiration date of raw materials, real-time operation management and recipe/insertion checks in each process, and recording of sterilization temperature and time. It is also possible to use optical character recognition (OCR) to read and record numerical displays on meters or equipment.

For handheld computer application examples in the food, pharmaceutical, and cosmetics industries, such as management efficiency improvement, error-proofing, and traceability assurance, click the button below.

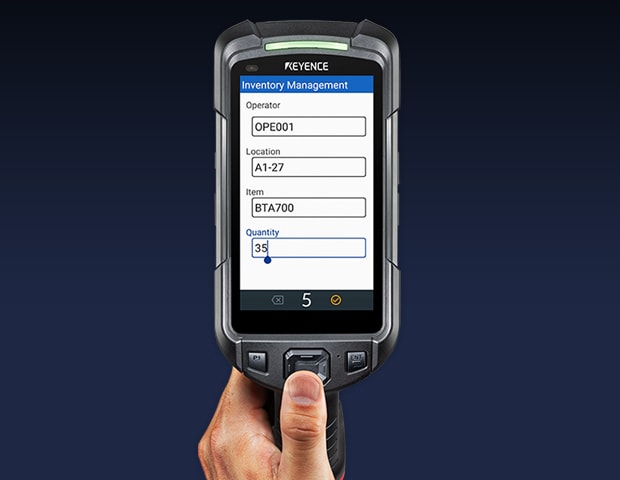

Inventory Managemet

Inventory management refers to maintaining the optimal number of items to match the situation.

there are many things subject to inventory management, it is effective to use an inventory management system in which barcodes and 2D codes are affixed to items and handheld mobile computers or similar devices are put to use.

First, read the barcodes for the item and its location (shelf, row, and level), and then enter information such as the quantity to register it. If location management has not been performed, generate barcodes and affix them to the shelves or similar locations. After all the items and locations have been registered, accurate stock management can be performed just by reading the barcodes during warehousing and when moving items. The data from operations such as warehousing and inventory can be checked in real time, which enables appropriate management.

Inspection of receiving goods

During the inspection of receiving goods, the delivered goods and the delivery slip that was sent together with the goods are verified to check that there are no problems with the product numbers and quantities and the goods are inspected for damage and problems in quality. If the inspection of receiving goods is performed visually, it is inevitable that some items be missed or read incorrectly, that the recording of some items in the ledger be forgotten, or that other similar errors occur. Mistakes that occur at this stage will be carried through to shelving and picking and may finally result in erroneous shipments. Handheld mobile computers can be used in this inspection of receiving goods to eliminate the majority of user-caused errors and thereby prevent erroneous shipments.

Traceabilety

Traceability is a word coined by combining “trace” and “ability.”

In traceability, the identification symbol used to transfer the information is called the expression pattern, the item on which data is recorded (such as a label or electronic tag) is called the transfer media, and the item such as a paper ledger or PC used to collect and manage data is called the recording media. The easiest traceability method is to write handwritten notes (the expression pattern) on slips (the transfer media) and rewrite this information in a ledger (the recording media). However, this method is a hassle and is inefficient in recording a large amount of information. Hence, handheld mobile computers and similar devices are most commonly used to read barcodes and 2D codes in order to obtain traceability.

Pokayoke (Error-proofing)

Mechanisms for detecting or preventing the generation of defects caused by careless mistakes, which are unavoidable at manufacturing worksites, is referred to as pokayoke (error-proofing).

There are various causes of careless mistakes at manufacturing worksites. Just a few examples are incorrectly reading product numbers, taking the wrong part, making mistakes in the setting of molds and jigs, and making mistakes in the blending of raw materials. Careless mistakes such as these can be prevented by thoroughly performing verification with handheld mobile computers. This section introduces pokayoke (error-proofing) using handheld mobile computers.

Frequently Asked Questions About Handheld Computers

Handheld code readers are a type of barcode reader specialized just for reading (scanning) codes. The readout data should be processed with a connected PC, so handheld code readers cannot be used separately from a PC and carried around like handheld computers.

On the other hand, handheld computers have an LCD screen, CPU, and memory built into the body. Programs can be embedded so that not only can they read data but they can also perform other required processing such as checking (displaying), matching, and saving data. Programs can be rewritten depending on the usage or purpose of the work. For example, you can set which of several information pieces obtained from one reading is to be entered automatically into which rows/columns in Excel.

The installation requires a variety of equipment such as a PC or a server to communicate with during operation, a battery that supplies the power and its charger, and a printer used to output data (when required). It is also necessary to develop software to provide system functions and operability that match the usage environment and the purpose. Examples of issues handled by the software include how to aggregate and process data or how to display the aggregated data on a PC screen.

On the other hand, some handheld computers are designed for simple operations by adopting a common platform, using dedicated software to create business programs quickly, and aggregating data as intended with Excel. Hence, it is important to consider the hardware, software, and other items suitable for the purpose, scale, and existing system, prior to installation.

The different handheld computer models have a wide variety of functions to match varying industries and applications. For example, to establish communication with a system within a large warehouse or store, select a type with a built-in wireless LAN interface. To perform work in a limited space, select a Bluetooth-equipped model.

There are cases in which recent inexpensive smartphones are used instead. This, however, may lead to expensive application development costs. Handheld computers are designed specifically for business purposes so that they can meet various needs in workplaces. Check the specifications such as the reading distance, speed, and accuracy for various codes and optical character recognition (OCR), as well as shock resistance, environmental resistance, and continuous usage time. It is also important to confirm the compatibility, availability, and whether technical support can be obtained or not.

Equipping an operator with the appropriate mobile computer enables them to speed up data collection for many business-critical applications (receiving, storage, inventory, picking, poka-yoke, traceability, shipping, etc.) by minimizing unnecessary trips to a work terminal. Utilizing barcode scanning, where possible, offers a nearly instantaneous data capture method over manual entry or pen & paper systems. Additionally, mobile computers can be connected to your business system to provide operators with immediate feedback and work instructions while they perform their responsibilities.

Adopting the right mobile computer device for your application should cut down on extraneous material and employee movement, lessen the frequency or severity of errors caused by mistakes, and increase overall operator productivity.

Companies of all industries rely on various systems to aid with core business operations. The nature and size of the business often dictate the characteristics of the ideal business system, by functionality and infrastructure. Data system technology is continuously evolving and a mobile computer device with a modern platform can adapt to fit the infrastructure of current or dated systems. From a technical standpoint, mobile computers can integrate into these systems via WLAN (WiFi) configurations with supported web browsers, telnet protocol, and remote desktop protocol (RDP), as well as Bluetooth connection, batch data transfer using a wired connection, or an application-specific embedded “App” on the mobile computer. Consult with your business system support team and mobile computer product expert to select the most effective solution.

To maximize the value of your mobile computer technology, consider the specifications that will best fit your operators’ needs. Device evaluation should consider factors that prioritize ease-of-use for the intended use of the mobile computer model. A few of these factors include the device’s screen size, form factor, battery capacity, and barcode scanning specifications. Work with a product expert to customize your mobile computer’s settings to the best possible configuration, such as restricting access to non-approved work applications on the device or optimizing the barcode scanning performance. Additionally, consider the desired lifespan of the mobile computer to minimize total cost of ownership. Review the mobile computer’s durability specifications (max. drop height, tumble rating, and ingress protection rating) and available maintenance packages with the manufacturer to protect your investment. Lastly, train your operators on proper usage.

This website describes basic knowledge about handheld computers and how to use them for each industry and operation. It also introduces installation examples by industry and application. Useful for everyone, from beginners to those considering system improvements.

![Read Any Text in an Instant [Logistics Industry]](jpg/as_109966_l.jpg)

Installing handheld mobile computers capable of reading non-barcode characters on location signage and product numbers can reduce errors that arise during visual inspection.

This guide summarizes the applications of handheld mobile computers. It provides easy-to-understand descriptions, from basic knowledge such as the abilities of handheld mobile computers, the environment required for installation, and successful applications, to installation examples by industry and important points on selecting handheld mobile computers.

This document summarizes solutions to eliminate shipping mistakes in the logistics industry. It describes ways to use handheld mobile computers to prevent mistakes when packages have no barcodes and to solve problems in various processes such as receiving, shelving, picking, and shipping inspection.

This document covers the system of logistics and basic knowledge of operations, the roles required of next-generation logistics, methods to improve efficiency, and operation improvement examples. It is packed with useful information and recommended to everyone involved in logistics from beginners to experts.