Applications and Examples of CAN Data Measurement

For automobiles equipped with an increasing number of electronic components to support higher performance, CAN data communication has now become indispensable. Although CAN was originally developed for automobiles, its applications have been expanded to include a wide variety of fields such as machine tools and medical equipment. This expansion has also increased the number of cases that require collection and analysis of CAN data. This section introduces examples of CAN measurement using a CAN data collection unit.

R&D applications

R&D applications

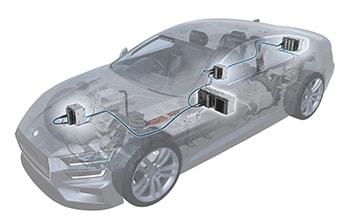

Automotive industryCollection of on-vehicle test data

CAN communication is used to collect data from automobile driving tests. The Multi-Input Data Collection System NR Series includes a CAN data collection unit, so you can obtain and analyze CAN data easily without any complicated settings. This product is ideal for measurement within a vehicle where a power supply is not readily available because this product’s compact body allows for easy handling even in a limited space on board. Even a large-capacity lithium ion battery can be connected to it. By adding a measurement unit, you can also collect and analyze multiple types of signals—including temperature, strain, pressure, and vibration signals—on a single unit, thereby enhancing the efficiency of your tests.

Automotive industryECU evaluation testing

The Multi-Input Data Collection System NR Series enables you to easily obtain various types of signals from ECUs by using a CAN data collection unit. One of the features is its function to collect CAN data from multi-signal, multi-system buses completely in sync with analog data. Its simple design and the fact that no programming is required, enable you to improve the efficiency of evaluation testing—a conventionally time-consuming operation.

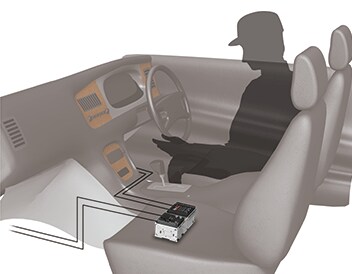

CAN data measurement with a multi-input data logger and a high-precision measurement unit

You can easily collect and analyze CAN data on vehicles, at factories, and at other locations by combining the Multi-Input Data Logger NR Series, which is packed with various evaluation and analysis functions on the smallest and lightest body in its class, with CAN data collection unit NR-C512. In addition to being able to handle CAN data, one of the features of the NR Series is its support over a wide range of measurements including temperature, acceleration, and strain.

CAN data collection unit NR-C512 collects CAN data from multi-signal, multi-system buses completely in sync with analog data. Through simple setting only possible with a dedicated bus monitor machine, you can start collecting CAN data without any programming. Its compact body is also ideal for use in a limited space such as on board.