Applications and Examples of Analog (Current/Voltage) Measurement

Signals output from various sensors—such as temperature, pressure, and flow rate—are consecutive “analog signals.” Therefore, R&D and production sites both rely on the measurement and recording of analog signals. This section introduces examples of typical analog (current/voltage) measurement in various industries (such as the automotive, metal/plastic, electronic device, and food industries). These examples are grouped into R&D and production site applications.

R&D applications

- Data collection during on-vehicle testing

- Displacement measurement during tension testing

- Evaluation of lithium ion batteries

Production site applications

R&D applications

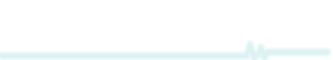

Automotive industryData collection during on-vehicle testing

During on-vehicle testing for automobiles, it is necessary to measure analog signals output from temperature and pressure sensors. Using the Multi-Input Data Collection System NR Series, you can measure and record multiple analog signals output from various sensors. Also, by adding a measurement unit, you can perform various types of measurement simultaneously with a single unit, despite its compact size, including measurement of temperature (such as intake and exhaust temperature), distortion (such as the deformation of the body during running), and CAN data output from the ECU.

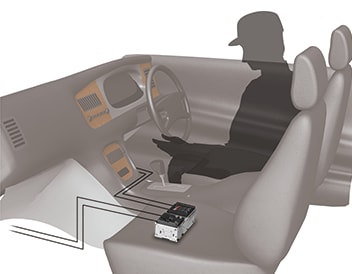

Metal and plastic industryDisplacement measurement during tension testing

During tension testing that evaluates mechanical properties of various materials, it is necessary to measure analog signals output from displacement sensors. As the term “multi-input” in its name implies, the Multi-Input Data Collection System NR Series is capable of simultaneously collecting multiple pieces of data, including not only analog outputs from displacement sensors, but also load data from strain gauges and load cells.

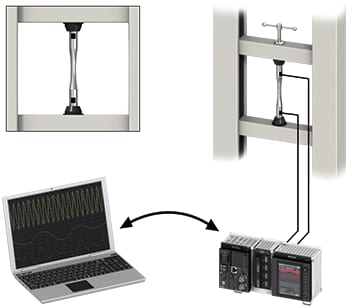

Electronic device industryEvaluation of lithium ion batteries

In the evaluation of the electrical properties of lithium ion batteries, it is necessary to measure the voltage with high accuracy to prevent overcharging. The high-speed, high-voltage measurement unit in the Multi-Input Data Collection System NR Series has a 14-bit resolution and a sampling cycle of 1 MHz, enabling this unit to support testing that requires high precision. Also, by using a temperature sensor, you can simultaneously record, for example, batteries’ abnormal heat generation and overcharging. As such, you can complete the evaluation of lithium ion batteries by using only a single unit.

Production site applications

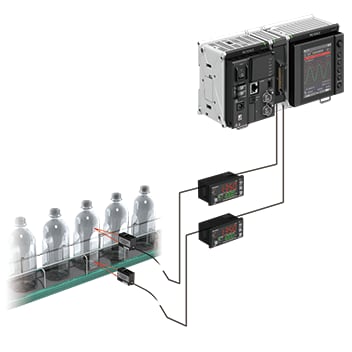

Food industryTemperature measurement of bottles after sterilization

During sterilization of glass and plastic bottles, it is necessary to record the temperature to ensure proper sterilization. You can determine whether bottles have been sterilized properly by measuring analog signals output from a thermometer and measuring and recording whether the temperature has risen to a certain level with the Multi-Input Data Collection System NR Series. Recording of temperature data is also effective in terms of traceability control as it ensures production safety through trend monitoring.

Metal and steel industryMulti-data collection for extruders

Stable production of extruded material requires control based on measured data such as temperature and pressure. The Multi-Input Data Collection System NR Series enables you to measure and record not only the temperature, pressure, extrusion rate, and discharge of dies in the extrusion process but also the outputs from dimension measuring instruments after molding. You can collect various pieces of detailed data during and after molding, thereby leading to a more stable extrusion molding line.

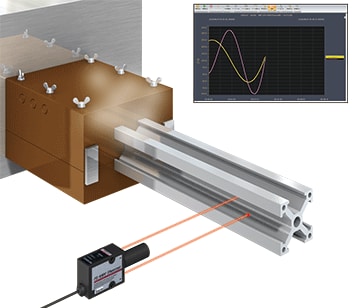

Metal and automotive industryData collection for processing machine tool run-out and vibration

Sensors are installed on processing machines to measure and record the run-out and vibration of tools. Through a comparison against data obtained during proper processing, you can identify, for example, tool deterioration and tool chuck errors. Such comparisons also work for predictive maintenance as you can detect changes from normal run-out and vibration at early stages. Maintenance and replacement before tools have deteriorated or broken will also lead to the reduction of defective products, making your production more efficient and stable.

Analog (current/voltage) measurement with a multi-input data logger and a high-speed analog measurement unit

You can integrate various types of measurement into a single unit by combining the Multi-Input Data Logger “NR Series,” which is packed with seven types of measurement functions on the smallest and lightest body in its class, with the high-speed analog measurement unit “NR-HA08” and the high-speed, high-voltage measurement unit “NR-HV04.”

The high-speed analog measurement unit “NR-HA08” features high specifications of 14-bit resolution and a sampling cycle of 1 MHz. This unit is also supplied with current (±20 mA). The high-speed, high-voltage measurement unit “NR-HV04” achieves completely simultaneous sampling with a maximum input of 1,000 V. This combination supports a wide variety of voltage measurements.

By adding a measurement unit, a single data logger can support seven types of measurement—including temperature, distortion, acceleration, and CAN data. Thanks to its compact body, you can easily carry the NR Series within a factory or during on-vehicle testing and its dedicated software also allows for easy setup and analysis. This multi-input data logger has been developed to completely solve problems that current conventional, difficult-to use data loggers have and to support a wide variety of measurements.